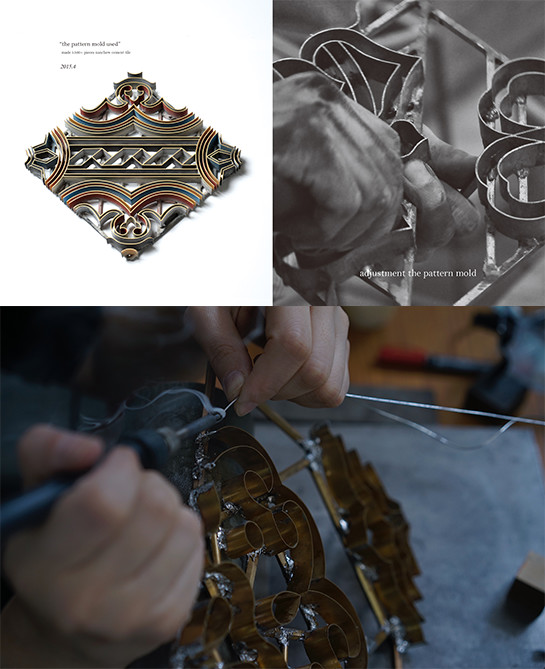

花砖图案分色模具是水泥花砖制作过程中的重要环节,每一款花砖图案都对应着一副到多副分色模具,在手工注浆步骤用于分离各彩色水泥层,为朴实的水泥材料赋予全然不同的图案与风格。

分色模具制作以铜片铜条为主体材料,由花模师根据图形弯折、桥接而成,根据设计方案全手工制作一副模具平均需要6-7天的时间。

一副好的分色模具需要精确到丝的平整度才能使成品花砖的图案线条有圆润清晰的可能,过程中的任何一个失误就有可能导致花模报损重做。

见南花花模目前调整了五次,最大区别就是使用的铜片铜条越来越薄,这就意味着水泥花砖的图案线条可以更细致,铜片铜条更容易弯折,可以制作图案更复杂的分色模具。我们也相应改进了锡焊的桥接方式,来解决花模的变形问题。目前铜片铜条最新试验调整的厚度是0.5mm。

做好的花模在生产水泥花砖的过程中,因为磨损的原因在制作大约2000片花砖后将报废。如何赋予这些失去生产价值的花模以新的功用,使它们的存在价值得以延续,是见南花再生设计重要的课题之一。

As a vital tool for making handcrafted cement tiles, the pattern colour separation mould endows ordinary cement with totally different patterns and styles.

The pattern colour separation mould is mainly produced with brass pieces and bars. It takes about 6-7 days for a mould maker to make one mould by hand in accordance with the design pattern.

Making a good colour separation mould requires the flatness accuracy within an admissible error of 0.01 millimeter, which make the lineation of finished cement tiles smooth and clear. Any mistakes occur in the process will lead to the reproduction of the mould.

NANCHOW has updated five times to improve the quality of the pattern mould continuously. The brass pieces and bars we use is thinner and thinner in order to make more complicated patterns. We also adjust the way of soldering accordingly to solve the problem of distortion of the mould. The newest brass pieces and bars we use is 0.05 millimeter.

Due to the wear and tear, a pattern mould may be scrapped after producing about 2000 cement tiles. Our designers are trying to endow the useless moulds with new functions and values, which is an important subject of NANCHOW.